Collaborative Research Projects

- Piping sYstem, Risk management based on wAll thinning MonItoring and preDiction (PYRAMID)

- Coupled computing of fluid-structure interaction problems for multiphase energy systems

- Modelling materials behavior for advanced electromagnetic Non Destructive Testing techniques

- Mathematical modeling and simulations of soft-elastic materials under large strain

- Numerical modelling of particle-laden effect on supersonic flow for cold-spray polymer coating

-

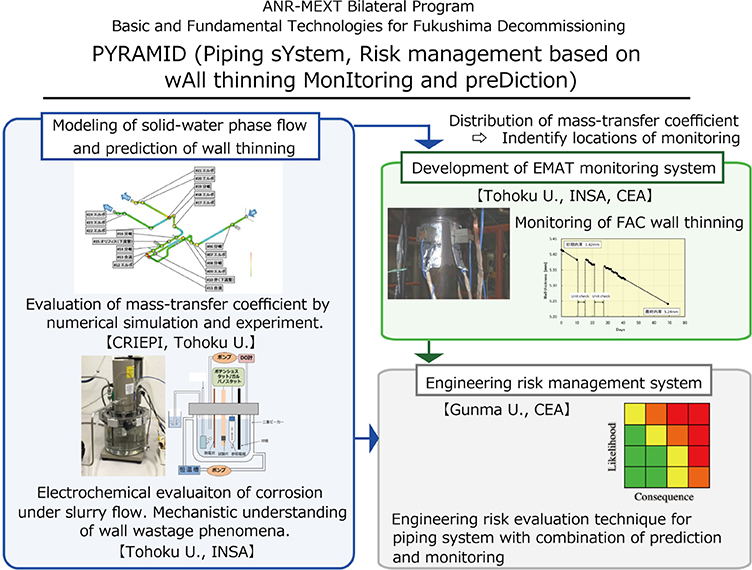

Piping sYstem, Risk management based on wAll thinning MonItoring and preDiction (PYRAMID)

Toshiyuki TAKAGI

Institute of Fluid Science, Tohoku UniversityThe project will address all the aspects of FAC, especially Slurry Flow induced Corrosion (SFC) from the mechanistic understanding of SFC due to disturbance of concentration boundary layer by repeated contact of particles, to the reaction rate evaluation, and tribo-corrosion effects.

PYRAMID goal is the definition of a multi-function, fully automated system not only mechanically but also in data processing and final diagnostics, inspection system that can detect both generalized and localized corrosion-erosion of piping systems in harsh environment. The targeted parts are carbon steel elbows in which flows a fluid with a high concentration of debris (cement slurry, corrosion and metallic particles…).

The results of the studies carried out in the project will be directly exploitable by the industrials, in particular in the context of the decommissioning of Japanese nuclear plants.

-

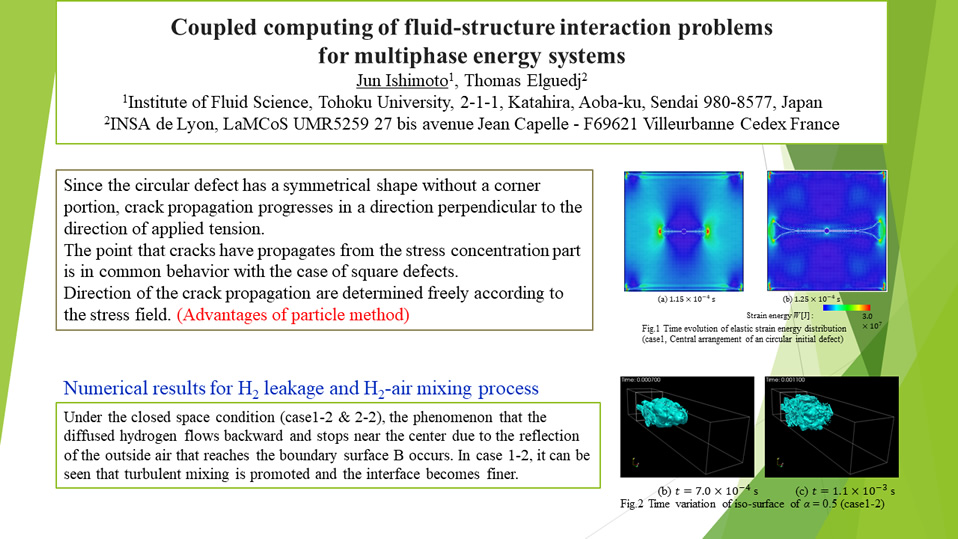

Coupled computing of fluid-structure interaction problems for multiphase energy systems

Jun ISHIMOTO

Institute of Fluid Science, Tohoku UniversityThis computational study provides advanced information for predicting arbitrary crack propagation of solid partition wall in pressure vessels accompany with leaked hydrogen-air mixing phenomena as an important part of assessing hydrogen as an energy vector. The present study was conducted by using a multiphysics of the coupled peridynamics and Euler computational methods.

-

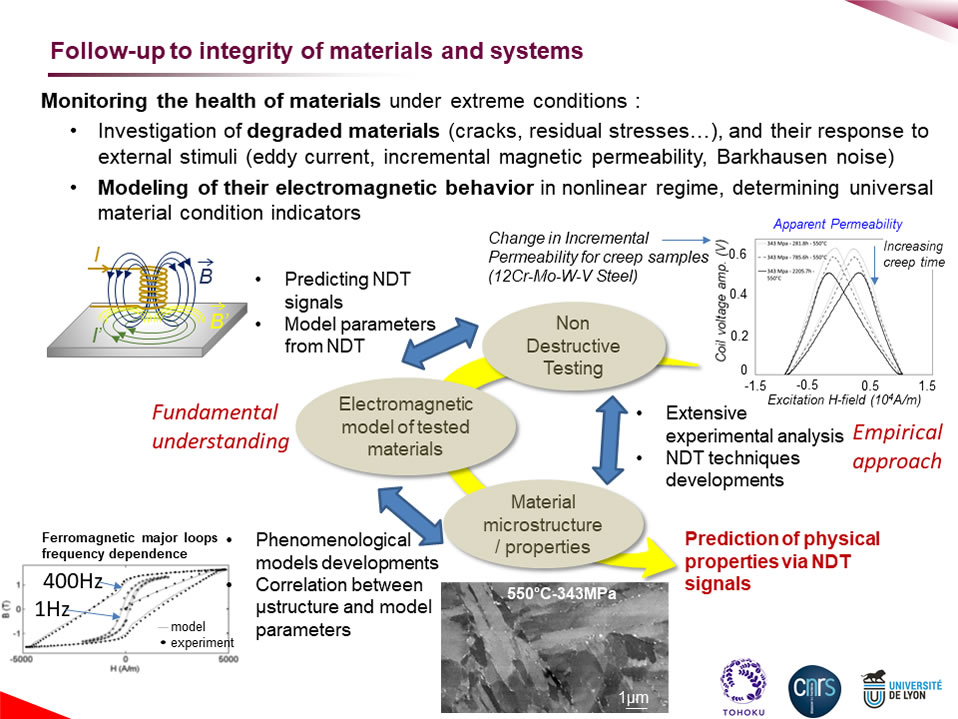

Modelling materials behavior for advanced electromagnetic Non Destructive Testing techniques

Gael SEBALD

CNRS, Université de Lyon, INSA-Lyon, Tohoku University• Development of ferromagnetic hysteresis models (e.g. application of Jiles-Atherton theory for understanding NDT signals).

• Magnetic Incremental Permeability and Barkhausen Noise on representative metallic samples.

• Comparison between NDT techniques revealing the microstructure.

In 3 years, this project led to 7 publications in international peer-reviewed journals, and 20 international conferences.

-

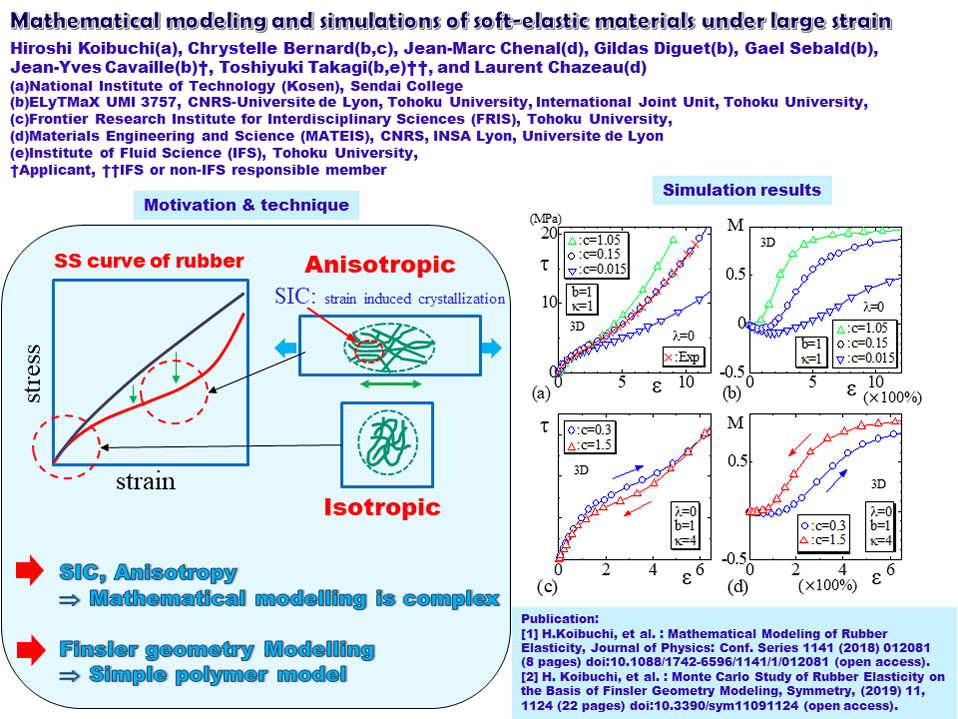

Mathematical modeling and simulations of soft-elastic materials under large strain

Jean-Yves CAVAILLE

Institute of Fluid Science, Tohoku UniversityMathematical modeling based on Finsler geometry is successfully applied to reproduce experimental data of stress-strain curves of rubbers up to 1200% by Monte Carlo simulations. Hysteresis behaviors observed in loading/unloading process can also be simulated with a suitable parameter variation.

-

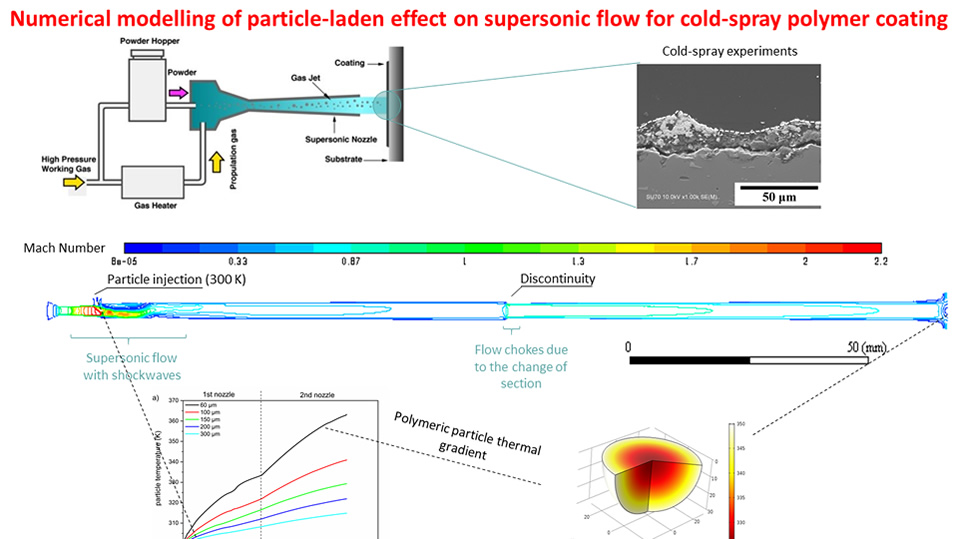

Numerical modelling of particle-laden effect on supersonic flow for cold-spray polymer coating

Chrystelle BERNARD

Frontier Research Institute for Interdisciplinary Sciences, Tohoku UniversityThe aim of this research is to obtain some insights of the polymer particles history inside the cold-spray nozzle. By understanding the evolution of the particle temperature and velocity inside the nozzle, we aim to analyze the probability of deposition or rebound of particles on a substrate.

Using a pressurized heated gas, particles heat up and accelerate through the cold-spray nozzle. Because polymers are sensitive to both strain rate and temperature, distribution of the particle temperature before impact is of a high importance.