Complex Flow Research Division

Advanced Fluid Machinery Systems Laboratory

ProfessorYuka Iga

Associate ProfessorJunnosuke Okajima

In this laboratory, complex flow phenomenon associated with high-speed gas-liquid mixture flows, especially about cavitation, is studied by using supercomputing and experiment. Additionally, advancement of fluid machinery systems with the mixture flows is investigated.

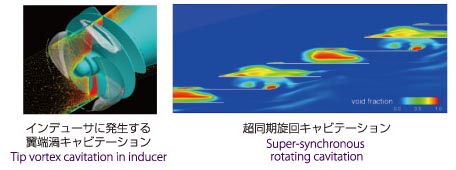

Study of Cavitation Instabilities in Liquid Propellant Rocket Turbopump

It is known that the volume of cavitation is suppressed due to decrease of temperature associated with latent heat of evaporation in liquid hydrogen and oxygen which are propellants of liquid rocket. But the actual degree of suppression of cavity volume cannot be predicted, then the suppression effect is not utilized in the design of the present rocket pumps. In this laboratory, in order to clarify the thermodynamic suppression effect, high-accuracy temperature measurement inside the cavity is done in hot water tunnel experiment in which the thermodynamic effect is same degree with that in the propellant and estimation of turbulent heat transfer is done in numerical simulation of cryogenic cavitation by using in-house thermal model.

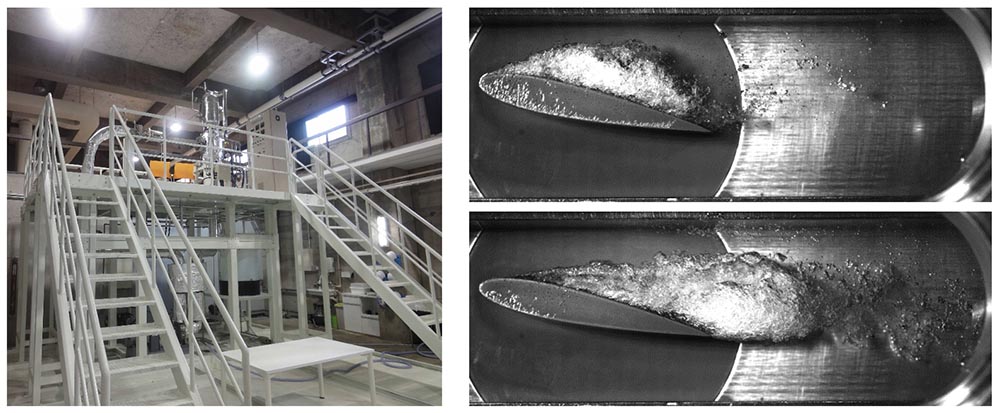

Clarification of Thermodynamic Suppression Effect of Cavitation

It is known that the volume of cavitation is suppressed due to decrease of temperature associated with latent heat of evaporation in liquid hydrogen and oxygen which are propellants of liquid rocket. But the actual degree of suppression of cavity volume cannot be predicted, then the suppression effect is not utilized in the design of the present rocket pumps. In this laboratory, in order to clarify the thermodynamic suppression effect, high-accuracy temperature measurement inside the cavity is done in hot water tunnel experiment in which the thermodynamic effect is same degree with that in the propellant and estimation of turbulent heat transfer is done in numerical simulation of cryogenic cavitation by using in-house thermal model.

Hot water cavitation tunnel facility and the aspects of cavitation around NACA0015 hydrofoil (140 ℃)

Hot water cavitation tunnel facility and the aspects of cavitation around NACA0015 hydrofoil (140 ℃)

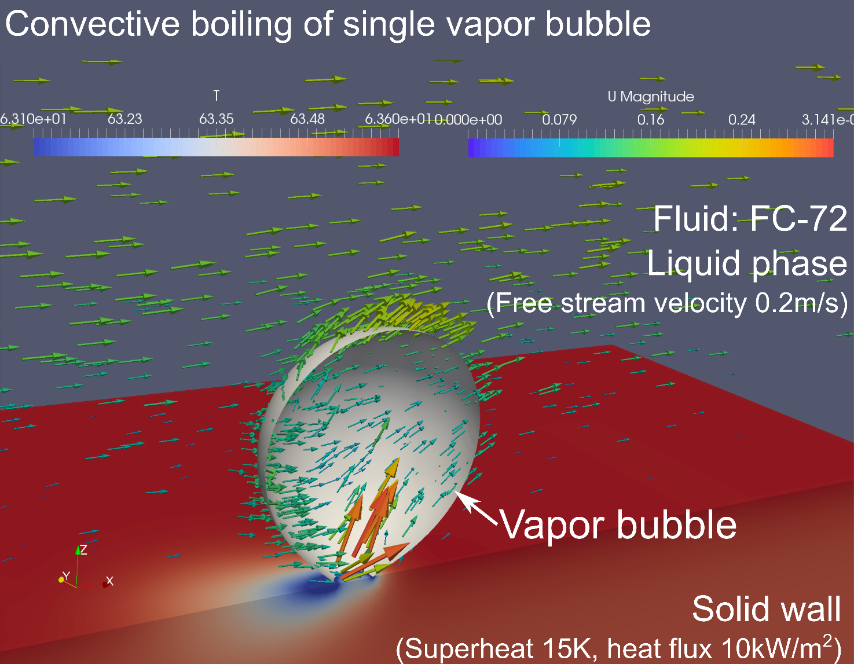

Thermal transport in two-phase flow with phase change and its application

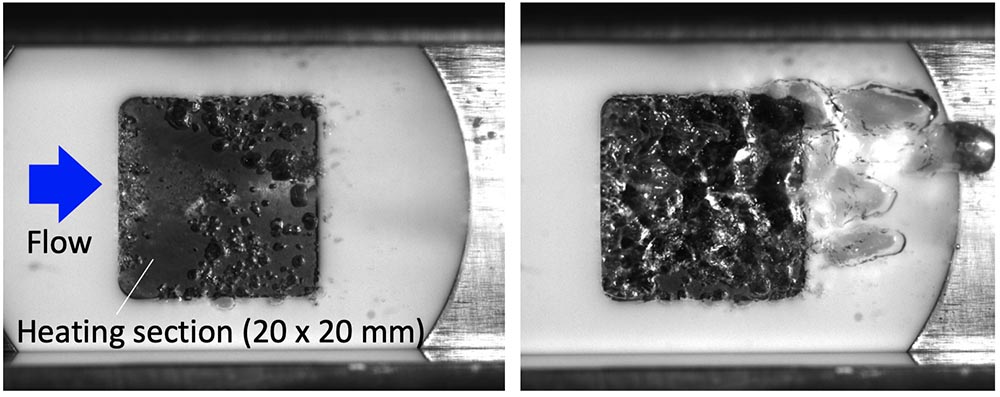

In cavitation or boiling flow, phase change such as evaporation and condensation occurs with heat transfer through a liquid-vapor interface. Additionally, thermal interaction between the two-phase fluid and the solid wall is affected by material properties and wettability. Because of such complex thermal transport in two-phase, the mathematical modeling and reproduction by numerical simulation of the evaporation process of single bubble boiling have not been enough yet. In this laboratory, to understand thermo-fluid phenomena through the interface, the analysis of the evaporation process around moving contact line, numerical simulation of boiling phenomena, and experiment of subcooled boiling in high-speed flow field are being conducted. We aim to contribute to the next-generation cooling system through the sophistication of these thermal transport mechanisms.

Numerical simulation of boiling heat transfer of single bubble in shear flow

Numerical simulation of boiling heat transfer of single bubble in shear flow Unsteady subcooled boiling flow in high-speed flow field

Unsteady subcooled boiling flow in high-speed flow field